FF-250™ Series Coalescing Filters

|

|

Further Information: |

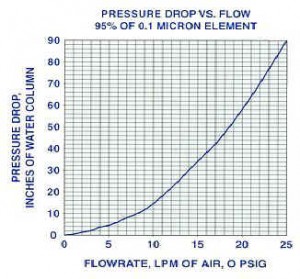

The FF-Series coalescing filters from Perma Pure are high efficiency particulate and coalescing filters designed for high temperature corrosive service. Used as a coalescer, this filter removes liquid droplets and particles down to 0.1 micron with an efficiency of 95% or greater. The thick, high capacity borosilicate glass and Teflon filter element uniformly drains coalesced liquids to the bottom of the housing, where they are evacuated through the 1/8″ NPT drain port. For particulates, the filter removes 95% of all particles 0.1 micron or greater, with a low pressure drop and long element life.

Coalescing filtration is achieved by forcing the gas stream through the filter element (see illustration). The flow path shown reflects a coalescing application. In this situation, small aerosol particles are forced together as they pass through the fine inner layer of the filter element. The larger drops created in this process fall out of the gas stream due to their mass. This natural separation is assisted by the coarse drain layer on the outside of the filter element. In a particulate application, this filter can be installed to reverse the flow path shown. The captured particulate then collects on the outside surface of the element, permitting visual determination of element condition.

FF-250 Series Coalescing Filter Specifications

| Model Number | FF-250-SG-2.5G | FF-250-FG-2.5G | FF-250-SS-2.5G |

| Housing Material | Stainless Steel | Teflon | Stainless Steel |

| Shell Material | Glass | Glass | Stainless Steel |

| Element (FF-250-E-2.5G) |

Borosilicate glass w/Teflon Binder with 1µm absolute porosity, 0.1 µm 99.3% removal |

||

| Maximum Temperature | 120 °C | 120 °C | 230 °C |

| Maximum Pressure |

30 psig |

||

| Inlet /Outlet and Drain Port |

1/8” FNPT |

||

| O-ring (FF-250-3) |

Viton – 3 per unit |

||

| Shell Volume |

200 cc |

||

FF-250 Series Filter Maintenance

All coalescing/ particulate filters should be checked regularly to ensure that the element is in good condition. The element should be replaced if it appears to be dirty or begins to cause a flow restriction in the system.

|

|